Tel: +86 15262904857 E-mail: overseas@jsbaileybridge.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Compact 200

BAILEY

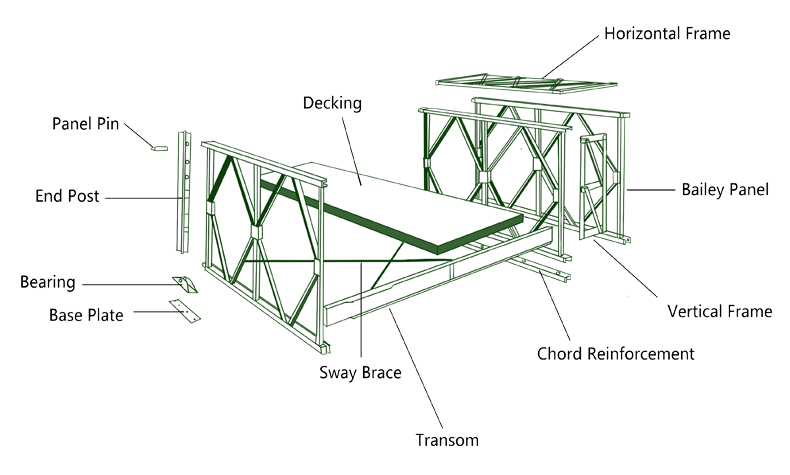

The Bailey Steel Bridge is a cutting-edge modular temporary bridge that redefines efficiency and flexibility in modern infrastructure projects. As a core prefabricated steel structure, it integrates innovative design with robust performance, catering to the dynamic needs of construction, emergency response, and temporary access scenarios. This modular temporary bridge eliminates the inefficiencies of traditional on-site construction, offering rapid deployment and seamless adaptation to diverse terrains—from urban construction sites to remote rural areas.

Attribute | Specification |

Product Name | Bailey steel bridge |

Standard Compliance | ASTM, BS, GB |

Material Grade | Q355-Q460C |

Product Type | Heavy |

Brand | Jiangsu Bailey |

Origin | Jiangsu, China |

Measurement Unit | Piece |

Tolerance | ±3% |

Annual Supply Capacity | 10000.0 Ton/Tons |

Customization | OK |

Loading Port | Any port of China (Main: Shanghai port) |

The prefabricated steel bridge’s modular design is its defining strength. All components are factory-manufactured to precise specifications, enabling on-site assembly without complex heavy machinery. This feature slashes construction time and labor costs, ensuring projects stay on track even with tight deadlines.

As a multi-purpose steel bridge, it transitions effortlessly from light pedestrian traffic to heavy-duty vehicle access. Its modular components allow easy adjustments to length and width, adapting to specific project requirements without compromising structural stability.

Crafted from high-grade steel, the corrosion-resistant Bailey bridge withstands harsh environmental conditions—from extreme temperatures to humid climates. Its robust material selection ensures long-term reliability, even in high-intensity usage scenarios.

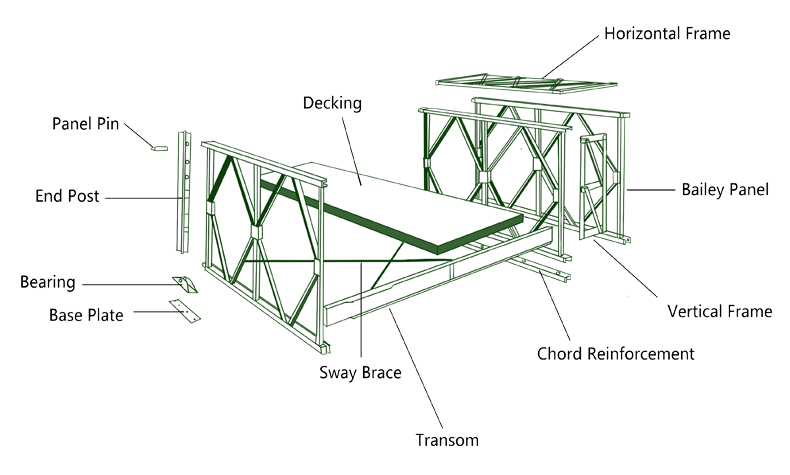

The bridge’s mechanism revolves around modular steel components that interlock seamlessly. Each part—from truss panels to connection pins—is engineered for precision, ensuring uniform load distribution and stable assembly. This design also simplifies transportation, as components can be stacked and shipped efficiently to remote locations.

The truss bridge framework adopts a triangular configuration, a time-tested design that enhances rigidity and load-bearing capacity. This structure efficiently disperses forces across the bridge, preventing stress concentration on individual components and supporting diverse load demands.

Engineered for reusability, the bridge’s mechanism allows straightforward dismantling. Components can be inspected, maintained, and reused in future projects, making this sustainable modular bridge an eco-friendly and cost-effective choice for forward-thinking projects.

| ZB200 truss press limited table | |||||||||

| structure form | |||||||||

| No | internal force | not reinforced model | reinforced model | ||||||

| SS | DS | TS | QS | SSR | DSR | TSR | QSR | ||

| 200 | standard truss moment(kN.m) | 1034.3 | 2027.2 | 2978.8 | 3930.3 | 2165.4 | 4244.2 | 6236.4 | 8228.6 |

| 200 | standard truss shear (kN) | 222.1 | 435.3 | 639.6 | 843.9 | 222.1 | 435.3 | 639.6 | 843.9 |

| 201 | high bending truss moment(kN.m) | 1593.2 | 3122.8 | 4585.5 | 6054.3 | 3335.8 | 6538.2 | 9607.1 | 12676.1 |

| 202 | high bending truss shear(kN) | 348 | 696 | 1044 | 1392 | 348 | 696 | 1044 | 1392 |

| 203 | Shear force of super high shear truss(kN) | 509.8 | 999.2 | 1468.2 | 1937.2 | 509.8 | 999.2 | 1468.2 | 1937.2 |

| ZB200 Table of geometric characteristics of truss bridge(Half bridge) | ||||

| structure | geometric characteristics | |||

| geometric characteristics | chord area(cm2) | Section properties(cm3) | Moment of inertia(cm4) | |

SS single-row, single-layer | SS single-row,single-layer | 25.48 | 5437 | 580174 |

SSR single-row,single-layer, reinforce | 50.96 | 10875 | 1160348 | |

DS double-row, single-layer | DS double-row,single-layer | 50.96 | 10875 | 1160348 |

| DSR1 double-row,single-layer, reinforced | 76.44 | 16312 | 1740522 | |

| DSR2 double-row,single-layer, reinforced only on the top | 101.92 | 21750 | 2320696 | |

TS triple-row, single-layer | TS triple-row,single-layer | 76.44 | 16312 | 1740522 |

| TSR2 triple-row,single-layer, reinforced only on the top | 127.4 | 27185 | 2900870 | |

| TSR3 triple-row,single-layer, reinforced only at the bottom | 152.88 | 32625 | 3481044 | |

| QS quadruple-row, single-layer | QS quadruple-row,single-layer | 101.92 | 21750 | 2320696 |

| QSR3 quadruple-row,single-layer, reinforced only on the top | 178.36 | 38059 | 4061218 | |

| QSR4 quadruple-row,single-layer, reinforced only at the bottom | 203.84 | 43500 | 4641392 | |

This temporary construction bridge serves as a critical link for construction vehicles and equipment, connecting job sites to main road networks. Its rapid assembly minimizes disruptions to ongoing work, while its durability withstands frequent use by heavy machinery.

In disaster-stricken areas, the emergency modular bridge acts as a lifeline, restoring transportation links for rescue teams, supplies, and affected communities. Its lightweight yet sturdy structure enables deployment in areas with limited access to heavy lifting equipment.

During road repairs or infrastructure upgrades, the temporary traffic bridge safely diverts vehicles and pedestrians, reducing congestion and maintaining public mobility. Its adaptability to urban and rural settings makes it a versatile tool for traffic management.

Production begins with selecting premium steel that meets global quality standards. Each batch undergoes rigorous inspection to ensure strength, corrosion resistance, and compatibility with modular manufacturing processes.

Using advanced machinery, technicians fabricate modular steel bridge components through precision cutting, bending, and welding. This ensures every part fits seamlessly with others, maintaining structural consistency across the entire bridge.

Components undergo professional surface treatment—including cleaning, coating, and finishing—to enhance corrosion resistance. This step protects the steel from environmental damage, extending the bridge’s service life.

Before shipment, pre-assembly tests verify component compatibility and structural stability. Each Bailey bridge module is inspected to ensure compliance with safety and performance standards, giving clients confidence in its reliability.

①

Raw Material

②

Sawing

③

Cutting

④

Shearing

⑤

Bending

⑥

Punching

⑦

Drilling

⑧

Welding

⑨

Surface Treatment

⑩

Semi-finished Products

⑪

Painting

⑫

Finished Products

As a leading Bailey bridge manufacturer, we bring years of experience in designing and producing modular steel bridges. Our engineering team understands the unique challenges of infrastructure projects, delivering tailored solutions that meet specific client needs.

Our ISO-certified steel bridge adheres to international standards such as ASTM and GB, ensuring compatibility with global construction requirements. Rigorous quality control processes guarantee consistent performance.

We offer end-to-end support—from initial design consultation to on-site installation guidance. Our technical team is available to address questions and resolve issues, ensuring smooth project implementation.

The reusable nature of our modular steel bridge reduces material waste and long-term project costs. We balance performance, sustainability, and economic value to deliver solutions that benefit both clients and the environment.

The Bailey Steel Bridge is a cutting-edge modular temporary bridge that redefines efficiency and flexibility in modern infrastructure projects. As a core prefabricated steel structure, it integrates innovative design with robust performance, catering to the dynamic needs of construction, emergency response, and temporary access scenarios. This modular temporary bridge eliminates the inefficiencies of traditional on-site construction, offering rapid deployment and seamless adaptation to diverse terrains—from urban construction sites to remote rural areas.

Attribute | Specification |

Product Name | Bailey steel bridge |

Standard Compliance | ASTM, BS, GB |

Material Grade | Q355-Q460C |

Product Type | Heavy |

Brand | Jiangsu Bailey |

Origin | Jiangsu, China |

Measurement Unit | Piece |

Tolerance | ±3% |

Annual Supply Capacity | 10000.0 Ton/Tons |

Customization | OK |

Loading Port | Any port of China (Main: Shanghai port) |

The prefabricated steel bridge’s modular design is its defining strength. All components are factory-manufactured to precise specifications, enabling on-site assembly without complex heavy machinery. This feature slashes construction time and labor costs, ensuring projects stay on track even with tight deadlines.

As a multi-purpose steel bridge, it transitions effortlessly from light pedestrian traffic to heavy-duty vehicle access. Its modular components allow easy adjustments to length and width, adapting to specific project requirements without compromising structural stability.

Crafted from high-grade steel, the corrosion-resistant Bailey bridge withstands harsh environmental conditions—from extreme temperatures to humid climates. Its robust material selection ensures long-term reliability, even in high-intensity usage scenarios.

The bridge’s mechanism revolves around modular steel components that interlock seamlessly. Each part—from truss panels to connection pins—is engineered for precision, ensuring uniform load distribution and stable assembly. This design also simplifies transportation, as components can be stacked and shipped efficiently to remote locations.

The truss bridge framework adopts a triangular configuration, a time-tested design that enhances rigidity and load-bearing capacity. This structure efficiently disperses forces across the bridge, preventing stress concentration on individual components and supporting diverse load demands.

Engineered for reusability, the bridge’s mechanism allows straightforward dismantling. Components can be inspected, maintained, and reused in future projects, making this sustainable modular bridge an eco-friendly and cost-effective choice for forward-thinking projects.

| ZB200 truss press limited table | |||||||||

| structure form | |||||||||

| No | internal force | not reinforced model | reinforced model | ||||||

| SS | DS | TS | QS | SSR | DSR | TSR | QSR | ||

| 200 | standard truss moment(kN.m) | 1034.3 | 2027.2 | 2978.8 | 3930.3 | 2165.4 | 4244.2 | 6236.4 | 8228.6 |

| 200 | standard truss shear (kN) | 222.1 | 435.3 | 639.6 | 843.9 | 222.1 | 435.3 | 639.6 | 843.9 |

| 201 | high bending truss moment(kN.m) | 1593.2 | 3122.8 | 4585.5 | 6054.3 | 3335.8 | 6538.2 | 9607.1 | 12676.1 |

| 202 | high bending truss shear(kN) | 348 | 696 | 1044 | 1392 | 348 | 696 | 1044 | 1392 |

| 203 | Shear force of super high shear truss(kN) | 509.8 | 999.2 | 1468.2 | 1937.2 | 509.8 | 999.2 | 1468.2 | 1937.2 |

| ZB200 Table of geometric characteristics of truss bridge(Half bridge) | ||||

| structure | geometric characteristics | |||

| geometric characteristics | chord area(cm2) | Section properties(cm3) | Moment of inertia(cm4) | |

SS single-row, single-layer | SS single-row,single-layer | 25.48 | 5437 | 580174 |

SSR single-row,single-layer, reinforce | 50.96 | 10875 | 1160348 | |

DS double-row, single-layer | DS double-row,single-layer | 50.96 | 10875 | 1160348 |

| DSR1 double-row,single-layer, reinforced | 76.44 | 16312 | 1740522 | |

| DSR2 double-row,single-layer, reinforced only on the top | 101.92 | 21750 | 2320696 | |

TS triple-row, single-layer | TS triple-row,single-layer | 76.44 | 16312 | 1740522 |

| TSR2 triple-row,single-layer, reinforced only on the top | 127.4 | 27185 | 2900870 | |

| TSR3 triple-row,single-layer, reinforced only at the bottom | 152.88 | 32625 | 3481044 | |

| QS quadruple-row, single-layer | QS quadruple-row,single-layer | 101.92 | 21750 | 2320696 |

| QSR3 quadruple-row,single-layer, reinforced only on the top | 178.36 | 38059 | 4061218 | |

| QSR4 quadruple-row,single-layer, reinforced only at the bottom | 203.84 | 43500 | 4641392 | |

This temporary construction bridge serves as a critical link for construction vehicles and equipment, connecting job sites to main road networks. Its rapid assembly minimizes disruptions to ongoing work, while its durability withstands frequent use by heavy machinery.

In disaster-stricken areas, the emergency modular bridge acts as a lifeline, restoring transportation links for rescue teams, supplies, and affected communities. Its lightweight yet sturdy structure enables deployment in areas with limited access to heavy lifting equipment.

During road repairs or infrastructure upgrades, the temporary traffic bridge safely diverts vehicles and pedestrians, reducing congestion and maintaining public mobility. Its adaptability to urban and rural settings makes it a versatile tool for traffic management.

Production begins with selecting premium steel that meets global quality standards. Each batch undergoes rigorous inspection to ensure strength, corrosion resistance, and compatibility with modular manufacturing processes.

Using advanced machinery, technicians fabricate modular steel bridge components through precision cutting, bending, and welding. This ensures every part fits seamlessly with others, maintaining structural consistency across the entire bridge.

Components undergo professional surface treatment—including cleaning, coating, and finishing—to enhance corrosion resistance. This step protects the steel from environmental damage, extending the bridge’s service life.

Before shipment, pre-assembly tests verify component compatibility and structural stability. Each Bailey bridge module is inspected to ensure compliance with safety and performance standards, giving clients confidence in its reliability.

①

Raw Material

②

Sawing

③

Cutting

④

Shearing

⑤

Bending

⑥

Punching

⑦

Drilling

⑧

Welding

⑨

Surface Treatment

⑩

Semi-finished Products

⑪

Painting

⑫

Finished Products

As a leading Bailey bridge manufacturer, we bring years of experience in designing and producing modular steel bridges. Our engineering team understands the unique challenges of infrastructure projects, delivering tailored solutions that meet specific client needs.

Our ISO-certified steel bridge adheres to international standards such as ASTM and GB, ensuring compatibility with global construction requirements. Rigorous quality control processes guarantee consistent performance.

We offer end-to-end support—from initial design consultation to on-site installation guidance. Our technical team is available to address questions and resolve issues, ensuring smooth project implementation.

The reusable nature of our modular steel bridge reduces material waste and long-term project costs. We balance performance, sustainability, and economic value to deliver solutions that benefit both clients and the environment.