Tel: +86 15262904857 E-mail: overseas@jsbaileybridge.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

HD200 Bailey Bridge

BAILEY

Q345B-Q460C

The large-span Bailey Steel Bridge is a high-quality modular bridge engineered to address the demands of major infrastructure projects requiring reliable cross-span connectivity. As a high-strength steel bridge, it combines advanced engineering with premium materials to deliver exceptional performance across wide gaps—including rivers, valleys, and highways. This durable modular bridge eliminates the limitations of traditional large-span construction, offering a cost-effective, efficient alternative that maintains structural stability even in challenging environments. Ideal for long-term infrastructure developments, industrial projects, and public works, it meets stringent global standards, making it a trusted choice for engineers and project managers tackling complex cross-span challenges.

The defining feature of this long-span steel bridge is its ability to cover extensive distances without intermediate supports. Its optimized design distributes weight evenly, enabling safe and stable passage across wide gaps while maintaining structural integrity.

Crafted from high-grade, high-strength steel, the bridge withstands heavy loads and frequent use. The material’s inherent robustness ensures it performs reliably in high-intensity applications—from industrial transportation to public infrastructure.

As a durable modular bridge, it resists wear, corrosion, and environmental stressors. The combination of premium materials and meticulous manufacturing ensures the bridge maintains performance over extended periods, reducing long-term maintenance costs.

The bridge’s mechanism is built around a robust steel truss structure, featuring triangular configurations that enhance rigidity and load-bearing capacity. This design efficiently disperses forces across the entire structure, minimizing stress on individual components and enabling large-span coverage.

Critical connection points are engineered with reinforced components, ensuring secure assembly and uniform load transfer. The modular connections are designed for strength and stability, even under heavy loads or dynamic traffic conditions.

The mechanism includes adaptive foundation interfaces, allowing the bridge to integrate with various foundation types—including concrete piers and steel supports. This flexibility enables deployment in diverse terrains, from flat urban areas to uneven rural landscapes.

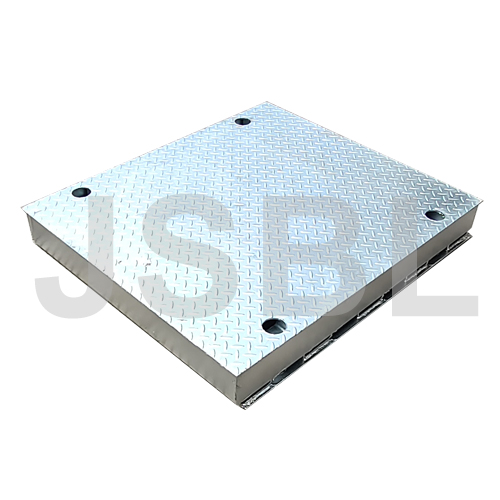

JSBL-016 Junction Deck

JSBL-011 Vertical Frame

JSBL-020 Ramp Bridge End Plate

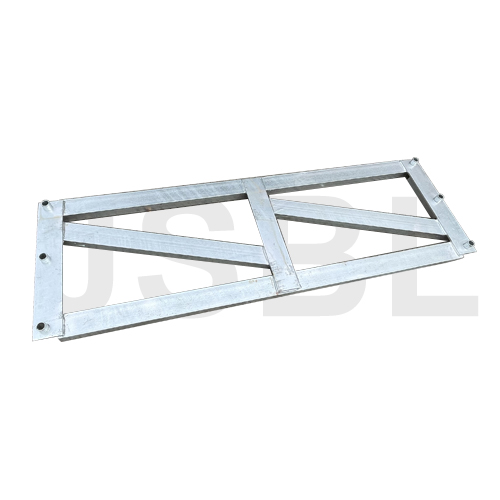

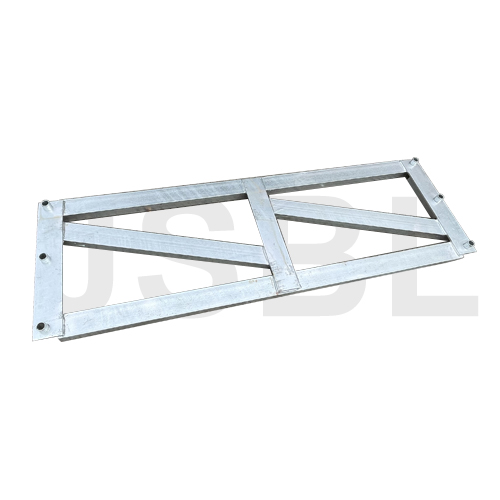

JSBL-010 Horizontal Frame

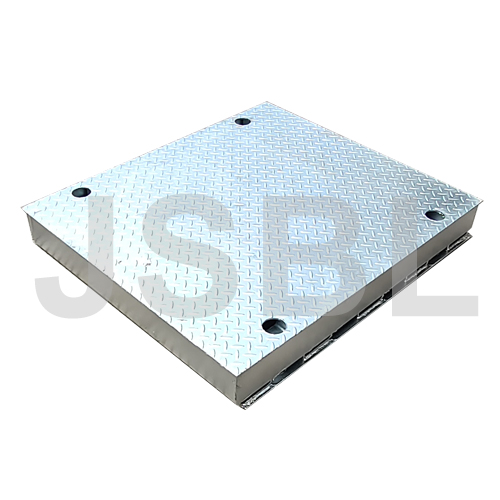

JSBL-028 Bearing

JSBL-039 Distributive Girder

| ZB200 truss press limited table | |||||||||

| structure form | |||||||||

| No | internal force | not reinforced model | reinforced model | ||||||

| SS | DS | TS | QS | SSR | DSR | TSR | QSR | ||

| 200 | standard truss moment(kN.m) | 1034.3 | 2027.2 | 2978.8 | 3930.3 | 2165.4 | 4244.2 | 6236.4 | 8228.6 |

| 200 | standard truss shear (kN) | 222.1 | 435.3 | 639.6 | 843.9 | 222.1 | 435.3 | 639.6 | 843.9 |

| 201 | high bending truss moment(kN.m) | 1593.2 | 3122.8 | 4585.5 | 6054.3 | 3335.8 | 6538.2 | 9607.1 | 12676.1 |

| 202 | high bending truss shear(kN) | 348 | 696 | 1044 | 1392 | 348 | 696 | 1044 | 1392 |

| 203 | Shear force of super high shear truss(kN) | 509.8 | 999.2 | 1468.2 | 1937.2 | 509.8 | 999.2 | 1468.2 | 1937.2 |

| ZB200 Table of geometric characteristics of truss bridge(Half bridge) | ||||

| structure | geometric characteristics | |||

| geometric characteristics | chord area(cm2) | Section properties(cm3) | Moment of inertia(cm4) | |

SS single-row, single-layer | SS single-row,single-layer | 25.48 | 5437 | 580174 |

SSR single-row,single-layer, reinforce | 50.96 | 10875 | 1160348 | |

DS double-row, single-layer | DS double-row,single-layer | 50.96 | 10875 | 1160348 |

| DSR1 double-row,single-layer, reinforced | 76.44 | 16312 | 1740522 | |

| DSR2 double-row,single-layer, reinforced only on the top | 101.92 | 21750 | 2320696 | |

TS triple-row, single-layer | TS triple-row,single-layer | 76.44 | 16312 | 1740522 |

| TSR2 triple-row,single-layer, reinforced only on the top | 127.4 | 27185 | 2900870 | |

| TSR3 triple-row,single-layer, reinforced only at the bottom | 152.88 | 32625 | 3481044 | |

| QS quadruple-row, single-layer | QS quadruple-row,single-layer | 101.92 | 21750 | 2320696 |

| QSR3 quadruple-row,single-layer, reinforced only on the top | 178.36 | 38059 | 4061218 | |

| QSR4 quadruple-row,single-layer, reinforced only at the bottom | 203.84 | 43500 | 4641392 | |

The production process begins with detailed engineering, where experts use cutting-edge software to design the large-span truss bridge according to project specifications. This phase includes structural analysis, load testing simulations, and optimization for large-span performance.

Using state-of-the-art machinery, factory teams manufacture each component with meticulous precision. From truss panels to connection hardware, every part is crafted to meet strict dimensional and strength requirements, ensuring seamless assembly.

Throughout production, each component undergoes multiple quality checks—including material strength testing, dimensional verification, and structural integrity inspections. This rigorous process ensures the final product meets or exceeds global safety and performance standards.

Before shipment, the bridge is partially assembled in the factory to verify component compatibility and structural stability. This pre-shipment testing identifies and resolves any issues, ensuring smooth on-site installation.

①

Raw Material

②

Sawing

③

Cutting

④

Shearing

⑤

Bending

⑥

Punching

⑦

Drilling

⑧

Welding

⑨

Surface Treatment

⑩

Semi-finished Products

⑪

Painting

⑫

Finished Products

We specialize in large-span Bailey bridge design and manufacturing, with a technical team experienced in addressing complex cross-span challenges. Our engineering expertise ensures each bridge is optimized for performance and safety.

Our products hold prestigious certifications, including ISO, ASTM, and GB, verifying compliance with global industry standards. These certifications reflect our commitment to delivering high-quality, reliable infrastructure solutions.

We offer comprehensive support—from initial design and customization to on-site installation and post-installation maintenance. Our team works closely with clients to ensure the bridge meets project timelines and performance expectations.

Our high-quality modular bridge has been deployed in major projects worldwide, earning trust from clients in diverse industries. We leverage our global experience to deliver tailored solutions that address local requirements and challenges.

The large-span Bailey Steel Bridge is a high-quality modular bridge engineered to address the demands of major infrastructure projects requiring reliable cross-span connectivity. As a high-strength steel bridge, it combines advanced engineering with premium materials to deliver exceptional performance across wide gaps—including rivers, valleys, and highways. This durable modular bridge eliminates the limitations of traditional large-span construction, offering a cost-effective, efficient alternative that maintains structural stability even in challenging environments. Ideal for long-term infrastructure developments, industrial projects, and public works, it meets stringent global standards, making it a trusted choice for engineers and project managers tackling complex cross-span challenges.

The defining feature of this long-span steel bridge is its ability to cover extensive distances without intermediate supports. Its optimized design distributes weight evenly, enabling safe and stable passage across wide gaps while maintaining structural integrity.

Crafted from high-grade, high-strength steel, the bridge withstands heavy loads and frequent use. The material’s inherent robustness ensures it performs reliably in high-intensity applications—from industrial transportation to public infrastructure.

As a durable modular bridge, it resists wear, corrosion, and environmental stressors. The combination of premium materials and meticulous manufacturing ensures the bridge maintains performance over extended periods, reducing long-term maintenance costs.

The bridge’s mechanism is built around a robust steel truss structure, featuring triangular configurations that enhance rigidity and load-bearing capacity. This design efficiently disperses forces across the entire structure, minimizing stress on individual components and enabling large-span coverage.

Critical connection points are engineered with reinforced components, ensuring secure assembly and uniform load transfer. The modular connections are designed for strength and stability, even under heavy loads or dynamic traffic conditions.

The mechanism includes adaptive foundation interfaces, allowing the bridge to integrate with various foundation types—including concrete piers and steel supports. This flexibility enables deployment in diverse terrains, from flat urban areas to uneven rural landscapes.

JSBL-016 Junction Deck

JSBL-011 Vertical Frame

JSBL-020 Ramp Bridge End Plate

JSBL-010 Horizontal Frame

JSBL-028 Bearing

JSBL-039 Distributive Girder

| ZB200 truss press limited table | |||||||||

| structure form | |||||||||

| No | internal force | not reinforced model | reinforced model | ||||||

| SS | DS | TS | QS | SSR | DSR | TSR | QSR | ||

| 200 | standard truss moment(kN.m) | 1034.3 | 2027.2 | 2978.8 | 3930.3 | 2165.4 | 4244.2 | 6236.4 | 8228.6 |

| 200 | standard truss shear (kN) | 222.1 | 435.3 | 639.6 | 843.9 | 222.1 | 435.3 | 639.6 | 843.9 |

| 201 | high bending truss moment(kN.m) | 1593.2 | 3122.8 | 4585.5 | 6054.3 | 3335.8 | 6538.2 | 9607.1 | 12676.1 |

| 202 | high bending truss shear(kN) | 348 | 696 | 1044 | 1392 | 348 | 696 | 1044 | 1392 |

| 203 | Shear force of super high shear truss(kN) | 509.8 | 999.2 | 1468.2 | 1937.2 | 509.8 | 999.2 | 1468.2 | 1937.2 |

| ZB200 Table of geometric characteristics of truss bridge(Half bridge) | ||||

| structure | geometric characteristics | |||

| geometric characteristics | chord area(cm2) | Section properties(cm3) | Moment of inertia(cm4) | |

SS single-row, single-layer | SS single-row,single-layer | 25.48 | 5437 | 580174 |

SSR single-row,single-layer, reinforce | 50.96 | 10875 | 1160348 | |

DS double-row, single-layer | DS double-row,single-layer | 50.96 | 10875 | 1160348 |

| DSR1 double-row,single-layer, reinforced | 76.44 | 16312 | 1740522 | |

| DSR2 double-row,single-layer, reinforced only on the top | 101.92 | 21750 | 2320696 | |

TS triple-row, single-layer | TS triple-row,single-layer | 76.44 | 16312 | 1740522 |

| TSR2 triple-row,single-layer, reinforced only on the top | 127.4 | 27185 | 2900870 | |

| TSR3 triple-row,single-layer, reinforced only at the bottom | 152.88 | 32625 | 3481044 | |

| QS quadruple-row, single-layer | QS quadruple-row,single-layer | 101.92 | 21750 | 2320696 |

| QSR3 quadruple-row,single-layer, reinforced only on the top | 178.36 | 38059 | 4061218 | |

| QSR4 quadruple-row,single-layer, reinforced only at the bottom | 203.84 | 43500 | 4641392 | |

The production process begins with detailed engineering, where experts use cutting-edge software to design the large-span truss bridge according to project specifications. This phase includes structural analysis, load testing simulations, and optimization for large-span performance.

Using state-of-the-art machinery, factory teams manufacture each component with meticulous precision. From truss panels to connection hardware, every part is crafted to meet strict dimensional and strength requirements, ensuring seamless assembly.

Throughout production, each component undergoes multiple quality checks—including material strength testing, dimensional verification, and structural integrity inspections. This rigorous process ensures the final product meets or exceeds global safety and performance standards.

Before shipment, the bridge is partially assembled in the factory to verify component compatibility and structural stability. This pre-shipment testing identifies and resolves any issues, ensuring smooth on-site installation.

①

Raw Material

②

Sawing

③

Cutting

④

Shearing

⑤

Bending

⑥

Punching

⑦

Drilling

⑧

Welding

⑨

Surface Treatment

⑩

Semi-finished Products

⑪

Painting

⑫

Finished Products

We specialize in large-span Bailey bridge design and manufacturing, with a technical team experienced in addressing complex cross-span challenges. Our engineering expertise ensures each bridge is optimized for performance and safety.

Our products hold prestigious certifications, including ISO, ASTM, and GB, verifying compliance with global industry standards. These certifications reflect our commitment to delivering high-quality, reliable infrastructure solutions.

We offer comprehensive support—from initial design and customization to on-site installation and post-installation maintenance. Our team works closely with clients to ensure the bridge meets project timelines and performance expectations.

Our high-quality modular bridge has been deployed in major projects worldwide, earning trust from clients in diverse industries. We leverage our global experience to deliver tailored solutions that address local requirements and challenges.