Tel: +86 15262904857 E-mail: overseas@jsbaileybridge.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

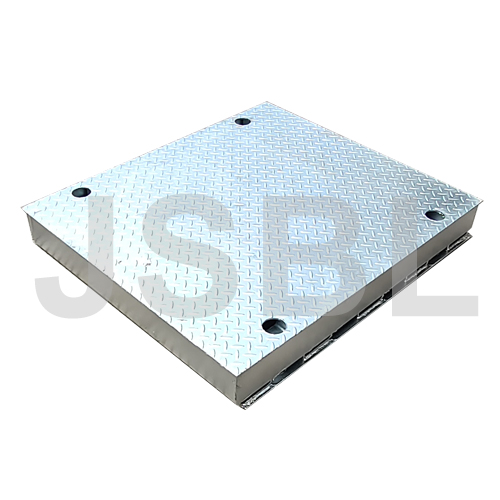

Introducing our professional-grade Bridge Deck, designed to meet the diverse load-bearing requirements and functionalities of various bridge structures. Our Bridge Deck is available in two variants: Steel Bridge Deck and Concrete and Wood Bridge Deck.

The Steel Bridge Deck is engineered to provide exceptional strength and durability, capable of withstanding heavy loads and harsh environmental conditions. Constructed with high-quality steel materials, it ensures long-lasting performance and minimal maintenance requirements. Its robust design offers reliable support and stability, making it an ideal choice for bridges that experience high traffic volumes or heavy-duty applications.

On the other hand, our Concrete and Wood Bridge Deck combines the strength of concrete with the natural aesthetics of wood. This innovative combination not only enhances the structural integrity of the bridge but also adds a touch of elegance to the overall design. The concrete base provides excellent load.

| Availability: | |

|---|---|

| Quantity: | |

Compact 200

BAILEY

Our Highway Temporary Bailey Steel Bridge is a top-tier structural solution designed to meet the dynamic needs of modern transportation projects. As a specialized temporary steel bridge manufacturer, we craft this product to adhere to strict international standards, ensuring it seamlessly integrates into highway construction, maintenance, and traffic diversion scenarios. This Bailey Steel Bridge combines robust performance with practical functionality, making it a trusted choice for engineers and project managers worldwide. Whether used as a short-term bypass or a temporary access route for heavy-duty vehicles, it delivers reliable service that aligns with diverse project requirements.

Constructed with premium Q355B-Q460C steel, our highway steel bridge boasts exceptional tensile strength and resistance to wear. It withstands heavy loads and frequent traffic without compromising structural integrity, even in challenging environmental conditions. The high-quality steel material also enhances its longevity, reducing the need for frequent replacements.

The modular steel bridge design allows for quick assembly and disassembly, minimizing downtime in highway projects. Each component is precision-engineered for seamless fitting, enabling on-site teams to deploy the bridge efficiently without specialized heavy equipment. This characteristic is crucial for meeting tight project deadlines and reducing labor costs.

Our temporary steel bridge features a corrosion-resistant surface treatment that protects against rust and environmental damage. This design reduces long-term maintenance efforts, allowing project teams to focus on core tasks rather than constant upkeep. The durable structure also resists wear from weather and traffic, ensuring consistent performance over its service life.

The steel truss bridge adopts a scientifically designed truss system that distributes loads evenly across the entire structure. This optimization enhances stability and load-bearing capacity, making the bridge suitable for heavy vehicles and high traffic volumes. The truss design also minimizes material usage while maximizing strength, achieving an optimal balance between performance and efficiency.

Each component of the Bailey Steel Bridge is designed with modularity in mind. The standardized connections ensure easy integration between parts, simplifying the assembly process. This mechanism also allows for flexible configuration, enabling the bridge to be adjusted to different lengths and widths based on project needs. The modular design also facilitates convenient storage and transportation when not in use.

①

Raw Material

②

Sawing

③

Cutting

④

Shearing

⑤

Bending

⑥

Punching

⑦

Drilling

⑧

Welding

⑨

Surface Treatment

⑩

Semi-finished Products

⑪

Painting

⑫

Finished Products

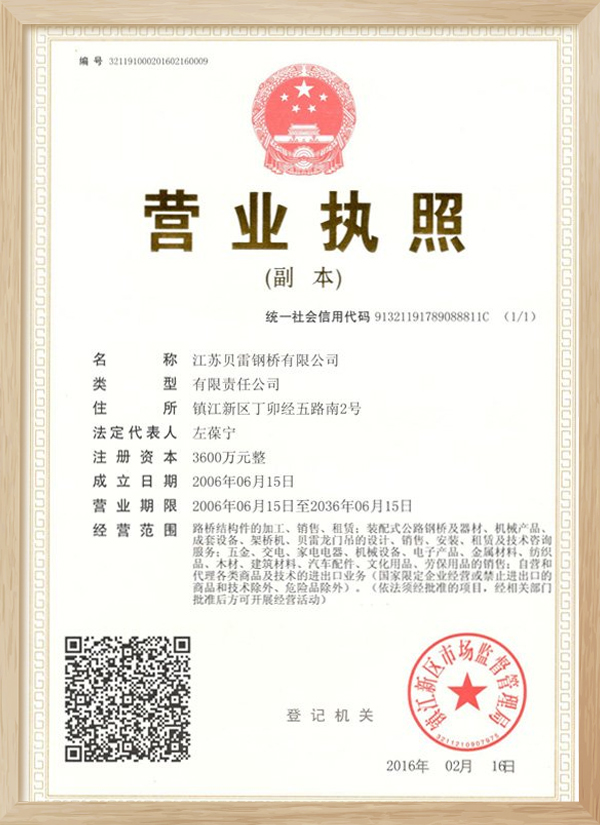

Our Bailey Steel Bridge is certified by ISO9001, CNAS, and other international authorities, ensuring it meets global quality and safety standards. These certifications reflect our commitment to delivering reliable products that exceed customer expectations.

With over 20 years of experience in manufacturing steel bridge structures, we have accumulated extensive knowledge and expertise in the field. Our team has successfully completed projects in numerous countries, demonstrating our ability to handle diverse project requirements.

We provide end-to-end after-sales support, including technical consultation, installation guidance, and maintenance advice. Our professional engineers are available to assist customers throughout the project lifecycle, ensuring smooth deployment and optimal performance of the bridge.

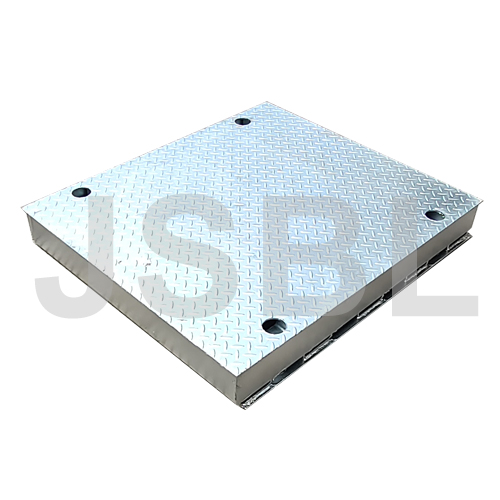

JSBL-016 Junction Deck

JSBL-011 Vertical Frame

JSBL-020 Ramp Bridge End Plate

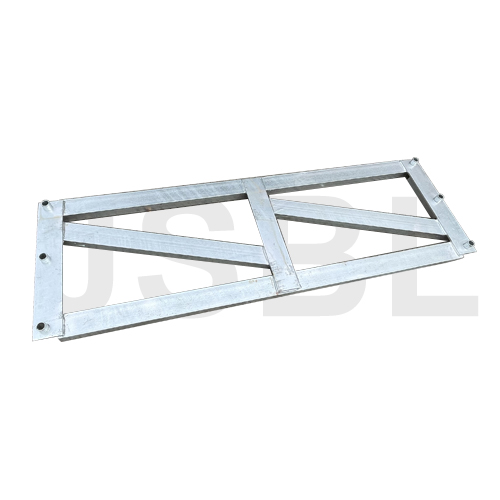

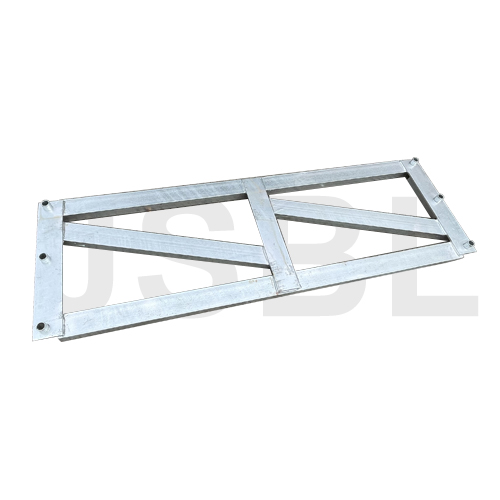

JSBL-010 Horizontal Frame

JSBL-028 Bearing

JSBL-039 Distributive Girder

| ZB200 truss press limited table | |||||||||

| structure form | |||||||||

| No | internal force | not reinforced model | reinforced model | ||||||

| SS | DS | TS | QS | SSR | DSR | TSR | QSR | ||

| 200 | standard truss moment(kN.m) | 1034.3 | 2027.2 | 2978.8 | 3930.3 | 2165.4 | 4244.2 | 6236.4 | 8228.6 |

| 200 | standard truss shear (kN) | 222.1 | 435.3 | 639.6 | 843.9 | 222.1 | 435.3 | 639.6 | 843.9 |

| 201 | high bending truss moment(kN.m) | 1593.2 | 3122.8 | 4585.5 | 6054.3 | 3335.8 | 6538.2 | 9607.1 | 12676.1 |

| 202 | high bending truss shear(kN) | 348 | 696 | 1044 | 1392 | 348 | 696 | 1044 | 1392 |

| 203 | Shear force of super high shear truss(kN) | 509.8 | 999.2 | 1468.2 | 1937.2 | 509.8 | 999.2 | 1468.2 | 1937.2 |

| ZB200 Table of geometric characteristics of truss bridge(Half bridge) | ||||

| structure | geometric characteristics | |||

| geometric characteristics | chord area(cm2) | Section properties(cm3) | Moment of inertia(cm4) | |

SS single-row, single-layer | SS single-row,single-layer | 25.48 | 5437 | 580174 |

SSR single-row,single-layer, reinforce | 50.96 | 10875 | 1160348 | |

DS double-row, single-layer | DS double-row,single-layer | 50.96 | 10875 | 1160348 |

| DSR1 double-row,single-layer, reinforced | 76.44 | 16312 | 1740522 | |

| DSR2 double-row,single-layer, reinforced only on the top | 101.92 | 21750 | 2320696 | |

TS triple-row, single-layer | TS triple-row,single-layer | 76.44 | 16312 | 1740522 |

| TSR2 triple-row,single-layer, reinforced only on the top | 127.4 | 27185 | 2900870 | |

| TSR3 triple-row,single-layer, reinforced only at the bottom | 152.88 | 32625 | 3481044 | |

| QS quadruple-row, single-layer | QS quadruple-row,single-layer | 101.92 | 21750 | 2320696 |

| QSR3 quadruple-row,single-layer, reinforced only on the top | 178.36 | 38059 | 4061218 | |

| QSR4 quadruple-row,single-layer, reinforced only at the bottom | 203.84 | 43500 | 4641392 | |

Our Highway Temporary Bailey Steel Bridge is a top-tier structural solution designed to meet the dynamic needs of modern transportation projects. As a specialized temporary steel bridge manufacturer, we craft this product to adhere to strict international standards, ensuring it seamlessly integrates into highway construction, maintenance, and traffic diversion scenarios. This Bailey Steel Bridge combines robust performance with practical functionality, making it a trusted choice for engineers and project managers worldwide. Whether used as a short-term bypass or a temporary access route for heavy-duty vehicles, it delivers reliable service that aligns with diverse project requirements.

Constructed with premium Q355B-Q460C steel, our highway steel bridge boasts exceptional tensile strength and resistance to wear. It withstands heavy loads and frequent traffic without compromising structural integrity, even in challenging environmental conditions. The high-quality steel material also enhances its longevity, reducing the need for frequent replacements.

The modular steel bridge design allows for quick assembly and disassembly, minimizing downtime in highway projects. Each component is precision-engineered for seamless fitting, enabling on-site teams to deploy the bridge efficiently without specialized heavy equipment. This characteristic is crucial for meeting tight project deadlines and reducing labor costs.

Our temporary steel bridge features a corrosion-resistant surface treatment that protects against rust and environmental damage. This design reduces long-term maintenance efforts, allowing project teams to focus on core tasks rather than constant upkeep. The durable structure also resists wear from weather and traffic, ensuring consistent performance over its service life.

The steel truss bridge adopts a scientifically designed truss system that distributes loads evenly across the entire structure. This optimization enhances stability and load-bearing capacity, making the bridge suitable for heavy vehicles and high traffic volumes. The truss design also minimizes material usage while maximizing strength, achieving an optimal balance between performance and efficiency.

Each component of the Bailey Steel Bridge is designed with modularity in mind. The standardized connections ensure easy integration between parts, simplifying the assembly process. This mechanism also allows for flexible configuration, enabling the bridge to be adjusted to different lengths and widths based on project needs. The modular design also facilitates convenient storage and transportation when not in use.

①

Raw Material

②

Sawing

③

Cutting

④

Shearing

⑤

Bending

⑥

Punching

⑦

Drilling

⑧

Welding

⑨

Surface Treatment

⑩

Semi-finished Products

⑪

Painting

⑫

Finished Products

Our Bailey Steel Bridge is certified by ISO9001, CNAS, and other international authorities, ensuring it meets global quality and safety standards. These certifications reflect our commitment to delivering reliable products that exceed customer expectations.

With over 20 years of experience in manufacturing steel bridge structures, we have accumulated extensive knowledge and expertise in the field. Our team has successfully completed projects in numerous countries, demonstrating our ability to handle diverse project requirements.

We provide end-to-end after-sales support, including technical consultation, installation guidance, and maintenance advice. Our professional engineers are available to assist customers throughout the project lifecycle, ensuring smooth deployment and optimal performance of the bridge.

JSBL-016 Junction Deck

JSBL-011 Vertical Frame

JSBL-020 Ramp Bridge End Plate

JSBL-010 Horizontal Frame

JSBL-028 Bearing

JSBL-039 Distributive Girder

| ZB200 truss press limited table | |||||||||

| structure form | |||||||||

| No | internal force | not reinforced model | reinforced model | ||||||

| SS | DS | TS | QS | SSR | DSR | TSR | QSR | ||

| 200 | standard truss moment(kN.m) | 1034.3 | 2027.2 | 2978.8 | 3930.3 | 2165.4 | 4244.2 | 6236.4 | 8228.6 |

| 200 | standard truss shear (kN) | 222.1 | 435.3 | 639.6 | 843.9 | 222.1 | 435.3 | 639.6 | 843.9 |

| 201 | high bending truss moment(kN.m) | 1593.2 | 3122.8 | 4585.5 | 6054.3 | 3335.8 | 6538.2 | 9607.1 | 12676.1 |

| 202 | high bending truss shear(kN) | 348 | 696 | 1044 | 1392 | 348 | 696 | 1044 | 1392 |

| 203 | Shear force of super high shear truss(kN) | 509.8 | 999.2 | 1468.2 | 1937.2 | 509.8 | 999.2 | 1468.2 | 1937.2 |

| ZB200 Table of geometric characteristics of truss bridge(Half bridge) | ||||

| structure | geometric characteristics | |||

| geometric characteristics | chord area(cm2) | Section properties(cm3) | Moment of inertia(cm4) | |

SS single-row, single-layer | SS single-row,single-layer | 25.48 | 5437 | 580174 |

SSR single-row,single-layer, reinforce | 50.96 | 10875 | 1160348 | |

DS double-row, single-layer | DS double-row,single-layer | 50.96 | 10875 | 1160348 |

| DSR1 double-row,single-layer, reinforced | 76.44 | 16312 | 1740522 | |

| DSR2 double-row,single-layer, reinforced only on the top | 101.92 | 21750 | 2320696 | |

TS triple-row, single-layer | TS triple-row,single-layer | 76.44 | 16312 | 1740522 |

| TSR2 triple-row,single-layer, reinforced only on the top | 127.4 | 27185 | 2900870 | |

| TSR3 triple-row,single-layer, reinforced only at the bottom | 152.88 | 32625 | 3481044 | |

| QS quadruple-row, single-layer | QS quadruple-row,single-layer | 101.92 | 21750 | 2320696 |

| QSR3 quadruple-row,single-layer, reinforced only on the top | 178.36 | 38059 | 4061218 | |

| QSR4 quadruple-row,single-layer, reinforced only at the bottom | 203.84 | 43500 | 4641392 | |