Tel: +86 15262904857 E-mail: overseas@jsbaileybridge.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Compact 200

BAILEY

Our cantilevered bridge truss stands as a core offering in the Bailey Steel Bridge lineup, engineered to address the complex crossing needs of large-scale infrastructure and civil engineering projects. As a premium steel bailey bridge variant, it integrates cantilevered design principles with modular flexibility, delivering reliable performance for both temporary and semi-permanent applications. Whether spanning wide waterways or challenging terrains, this truss bridge combines structural integrity with cost-effectiveness, making it a preferred choice for engineers and project managers worldwide.

Attribute | Value |

Application | Heavy-duty access bridge for a major channel improvement project |

Location | Qinhuai River, Nanjing, Jiangsu Province, China |

Total Length | 108 meters (354 feet), configured in 5 spans of 21.6m each |

Superstructure | Type 321, Double-Row, Single-Layer, Reinforced (DSR) |

Substructure | Custom 630mm x 10mm steel pipe piers |

Crafted from high-grade structural steel, the cantilevered bridge truss boasts exceptional strength and resilience. The material’s inherent durability ensures resistance to heavy loads and harsh operating conditions, extending the bridge’s service life.

The modular construction allows for quick assembly and disassembly, while the cantilevered structure eliminates the need for intermediate supports in specific scenarios. This design flexibility makes the bridge adaptable to diverse project requirements.

Equipped with integrated pedestrian guardrails, anti-slip decking, and safety curbs, the steel bailey bridge prioritizes the protection of both vehicle and foot traffic. Every component undergoes rigorous safety testing to meet global standards.

Advanced surface treatment technologies shield the truss bridge from corrosion, moisture, and extreme temperatures. This weather resistance ensures consistent performance in outdoor environments, regardless of climate conditions.

The truss framework is engineered with precision, featuring interconnected members that distribute stress evenly across the structure. This optimized configuration enhances load-bearing efficiency while reducing overall weight.

The cantilevered bridge truss seamlessly pairs with custom-designed steel piers, creating a stable foundation that adapts to different ground conditions. The substructure’s robust design complements the cantilevered mechanism, ensuring structural stability.

The cantilevered design transfers loads from the outer spans to the main supports, leveraging tension and compression forces within the truss members. This efficient load-bearing mechanism enables the bridge to handle heavy construction vehicles and equipment.

①

Raw Material

②

Sawing

③

Cutting

④

Shearing

⑤

Bending

⑥

Punching

⑦

Drilling

⑧

Welding

⑨

Surface Treatment

⑩

Semi-finished Products

⑪

Painting

⑫

Finished Products

With years of experience in designing and manufacturing steel bailey bridges, we possess the technical knowledge to deliver tailored solutions for complex projects.

Our team of engineers collaborates with clients to develop custom truss bridge designs that align with specific project requirements, from span length to load capacity.

Every cantilevered bridge truss undergoes comprehensive testing, adhering to international standards such as ASTM and GB. Our quality control processes leave no room for compromise.

We have successfully delivered steel bailey bridge solutions to projects across Asia, Africa, and South America, demonstrating our ability to adapt to diverse regional requirements.

From installation guidance to maintenance advice, our after-sales team provides ongoing support to ensure the truss bridge operates at peak performance throughout its lifecycle.

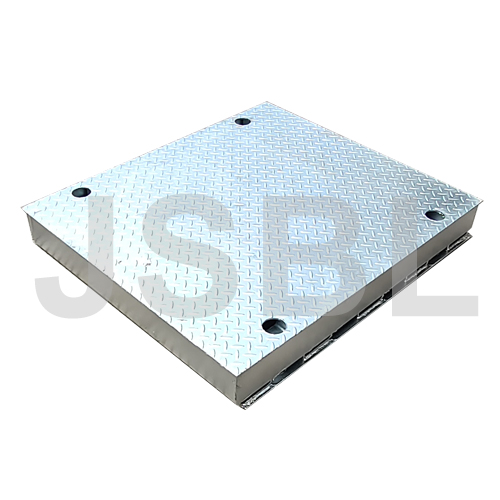

JSBL-016 Junction Deck

JSBL-011 Vertical Frame

JSBL-020 Ramp Bridge End Plate

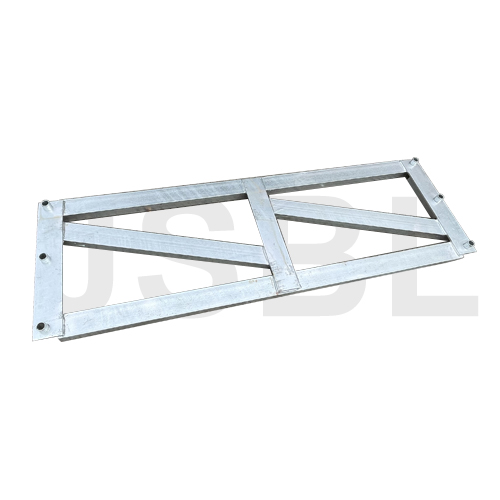

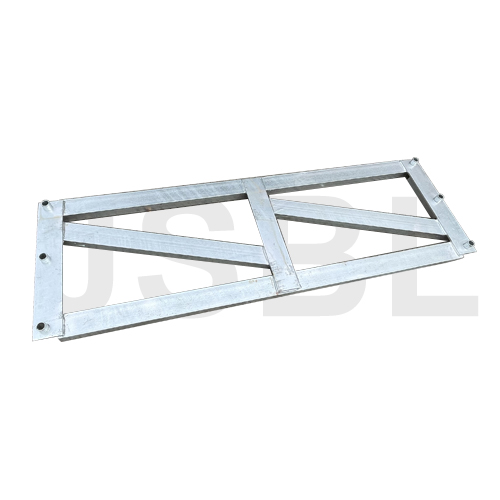

JSBL-010 Horizontal Frame

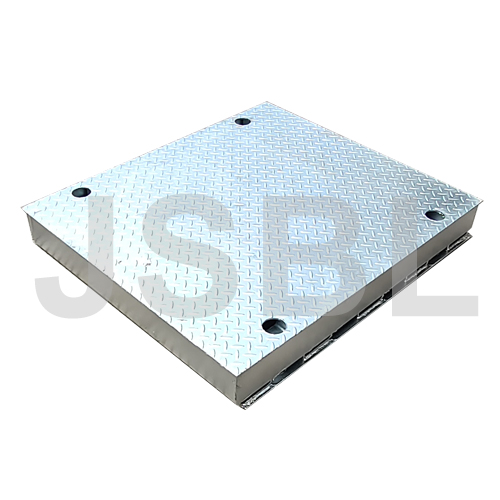

JSBL-028 Bearing

JSBL-039 Distributive Girder

| ZB200 truss press limited table | |||||||||

| structure form | |||||||||

| No | internal force | not reinforced model | reinforced model | ||||||

| SS | DS | TS | QS | SSR | DSR | TSR | QSR | ||

| 200 | standard truss moment(kN.m) | 1034.3 | 2027.2 | 2978.8 | 3930.3 | 2165.4 | 4244.2 | 6236.4 | 8228.6 |

| 200 | standard truss shear (kN) | 222.1 | 435.3 | 639.6 | 843.9 | 222.1 | 435.3 | 639.6 | 843.9 |

| 201 | high bending truss moment(kN.m) | 1593.2 | 3122.8 | 4585.5 | 6054.3 | 3335.8 | 6538.2 | 9607.1 | 12676.1 |

| 202 | high bending truss shear(kN) | 348 | 696 | 1044 | 1392 | 348 | 696 | 1044 | 1392 |

| 203 | Shear force of super high shear truss(kN) | 509.8 | 999.2 | 1468.2 | 1937.2 | 509.8 | 999.2 | 1468.2 | 1937.2 |

| ZB200 Table of geometric characteristics of truss bridge(Half bridge) | ||||

| structure | geometric characteristics | |||

| geometric characteristics | chord area(cm2) | Section properties(cm3) | Moment of inertia(cm4) | |

SS single-row, single-layer | SS single-row,single-layer | 25.48 | 5437 | 580174 |

SSR single-row,single-layer, reinforce | 50.96 | 10875 | 1160348 | |

DS double-row, single-layer | DS double-row,single-layer | 50.96 | 10875 | 1160348 |

| DSR1 double-row,single-layer, reinforced | 76.44 | 16312 | 1740522 | |

| DSR2 double-row,single-layer, reinforced only on the top | 101.92 | 21750 | 2320696 | |

TS triple-row, single-layer | TS triple-row,single-layer | 76.44 | 16312 | 1740522 |

| TSR2 triple-row,single-layer, reinforced only on the top | 127.4 | 27185 | 2900870 | |

| TSR3 triple-row,single-layer, reinforced only at the bottom | 152.88 | 32625 | 3481044 | |

| QS quadruple-row, single-layer | QS quadruple-row,single-layer | 101.92 | 21750 | 2320696 |

| QSR3 quadruple-row,single-layer, reinforced only on the top | 178.36 | 38059 | 4061218 | |

| QSR4 quadruple-row,single-layer, reinforced only at the bottom | 203.84 | 43500 | 4641392 | |

Nanjing

Nanjing

Nanjing

Our cantilevered bridge truss stands as a core offering in the Bailey Steel Bridge lineup, engineered to address the complex crossing needs of large-scale infrastructure and civil engineering projects. As a premium steel bailey bridge variant, it integrates cantilevered design principles with modular flexibility, delivering reliable performance for both temporary and semi-permanent applications. Whether spanning wide waterways or challenging terrains, this truss bridge combines structural integrity with cost-effectiveness, making it a preferred choice for engineers and project managers worldwide.

Attribute | Value |

Application | Heavy-duty access bridge for a major channel improvement project |

Location | Qinhuai River, Nanjing, Jiangsu Province, China |

Total Length | 108 meters (354 feet), configured in 5 spans of 21.6m each |

Superstructure | Type 321, Double-Row, Single-Layer, Reinforced (DSR) |

Substructure | Custom 630mm x 10mm steel pipe piers |

Crafted from high-grade structural steel, the cantilevered bridge truss boasts exceptional strength and resilience. The material’s inherent durability ensures resistance to heavy loads and harsh operating conditions, extending the bridge’s service life.

The modular construction allows for quick assembly and disassembly, while the cantilevered structure eliminates the need for intermediate supports in specific scenarios. This design flexibility makes the bridge adaptable to diverse project requirements.

Equipped with integrated pedestrian guardrails, anti-slip decking, and safety curbs, the steel bailey bridge prioritizes the protection of both vehicle and foot traffic. Every component undergoes rigorous safety testing to meet global standards.

Advanced surface treatment technologies shield the truss bridge from corrosion, moisture, and extreme temperatures. This weather resistance ensures consistent performance in outdoor environments, regardless of climate conditions.

The truss framework is engineered with precision, featuring interconnected members that distribute stress evenly across the structure. This optimized configuration enhances load-bearing efficiency while reducing overall weight.

The cantilevered bridge truss seamlessly pairs with custom-designed steel piers, creating a stable foundation that adapts to different ground conditions. The substructure’s robust design complements the cantilevered mechanism, ensuring structural stability.

The cantilevered design transfers loads from the outer spans to the main supports, leveraging tension and compression forces within the truss members. This efficient load-bearing mechanism enables the bridge to handle heavy construction vehicles and equipment.

①

Raw Material

②

Sawing

③

Cutting

④

Shearing

⑤

Bending

⑥

Punching

⑦

Drilling

⑧

Welding

⑨

Surface Treatment

⑩

Semi-finished Products

⑪

Painting

⑫

Finished Products

With years of experience in designing and manufacturing steel bailey bridges, we possess the technical knowledge to deliver tailored solutions for complex projects.

Our team of engineers collaborates with clients to develop custom truss bridge designs that align with specific project requirements, from span length to load capacity.

Every cantilevered bridge truss undergoes comprehensive testing, adhering to international standards such as ASTM and GB. Our quality control processes leave no room for compromise.

We have successfully delivered steel bailey bridge solutions to projects across Asia, Africa, and South America, demonstrating our ability to adapt to diverse regional requirements.

From installation guidance to maintenance advice, our after-sales team provides ongoing support to ensure the truss bridge operates at peak performance throughout its lifecycle.

JSBL-016 Junction Deck

JSBL-011 Vertical Frame

JSBL-020 Ramp Bridge End Plate

JSBL-010 Horizontal Frame

JSBL-028 Bearing

JSBL-039 Distributive Girder

| ZB200 truss press limited table | |||||||||

| structure form | |||||||||

| No | internal force | not reinforced model | reinforced model | ||||||

| SS | DS | TS | QS | SSR | DSR | TSR | QSR | ||

| 200 | standard truss moment(kN.m) | 1034.3 | 2027.2 | 2978.8 | 3930.3 | 2165.4 | 4244.2 | 6236.4 | 8228.6 |

| 200 | standard truss shear (kN) | 222.1 | 435.3 | 639.6 | 843.9 | 222.1 | 435.3 | 639.6 | 843.9 |

| 201 | high bending truss moment(kN.m) | 1593.2 | 3122.8 | 4585.5 | 6054.3 | 3335.8 | 6538.2 | 9607.1 | 12676.1 |

| 202 | high bending truss shear(kN) | 348 | 696 | 1044 | 1392 | 348 | 696 | 1044 | 1392 |

| 203 | Shear force of super high shear truss(kN) | 509.8 | 999.2 | 1468.2 | 1937.2 | 509.8 | 999.2 | 1468.2 | 1937.2 |

| ZB200 Table of geometric characteristics of truss bridge(Half bridge) | ||||

| structure | geometric characteristics | |||

| geometric characteristics | chord area(cm2) | Section properties(cm3) | Moment of inertia(cm4) | |

SS single-row, single-layer | SS single-row,single-layer | 25.48 | 5437 | 580174 |

SSR single-row,single-layer, reinforce | 50.96 | 10875 | 1160348 | |

DS double-row, single-layer | DS double-row,single-layer | 50.96 | 10875 | 1160348 |

| DSR1 double-row,single-layer, reinforced | 76.44 | 16312 | 1740522 | |

| DSR2 double-row,single-layer, reinforced only on the top | 101.92 | 21750 | 2320696 | |

TS triple-row, single-layer | TS triple-row,single-layer | 76.44 | 16312 | 1740522 |

| TSR2 triple-row,single-layer, reinforced only on the top | 127.4 | 27185 | 2900870 | |

| TSR3 triple-row,single-layer, reinforced only at the bottom | 152.88 | 32625 | 3481044 | |

| QS quadruple-row, single-layer | QS quadruple-row,single-layer | 101.92 | 21750 | 2320696 |

| QSR3 quadruple-row,single-layer, reinforced only on the top | 178.36 | 38059 | 4061218 | |

| QSR4 quadruple-row,single-layer, reinforced only at the bottom | 203.84 | 43500 | 4641392 | |

Nanjing

Nanjing

Nanjing