Tel: +86 15262904857 E-mail: overseas@jsbaileybridge.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Whether used for disaster relief, emergency construction, or temporary access to remote areas, this bridge delivers unparalleled performance when time is of the essence.

| Availability: | |

|---|---|

| Quantity: | |

Compact 200

BAILEY

Our Emergency Prefabricated Steel Bridge is a game-changing solution designed for urgent access needs in critical situations. As a leading prefabricated steel bridge manufacturer, we prioritize speed, reliability, and durability in every unit we produce. This emergency steel bridge is engineered to be deployed quickly, providing immediate access in the aftermath of natural disasters, infrastructure failures, or unexpected emergencies. It adheres to global standards such as ASTM and GB, ensuring it can withstand extreme conditions while supporting safe and efficient traffic flow.

Specification | Details |

Standard | ASTM, BS, GB |

Grade | Q345B-Q460C |

Place of Origin | Jiangsu, China |

Brand Name | BAILEY |

Model Number | JSBLGQ-HD200-071 |

Type | Heavy |

Application | Steel Structure Bridge |

Tolerance | ±3% |

Supply Ability | 10000.0 Ton/Tons per Year |

Packaging Details | packing in containers or bulk |

Port of Loading | Any port of China, main port is Shanghai port |

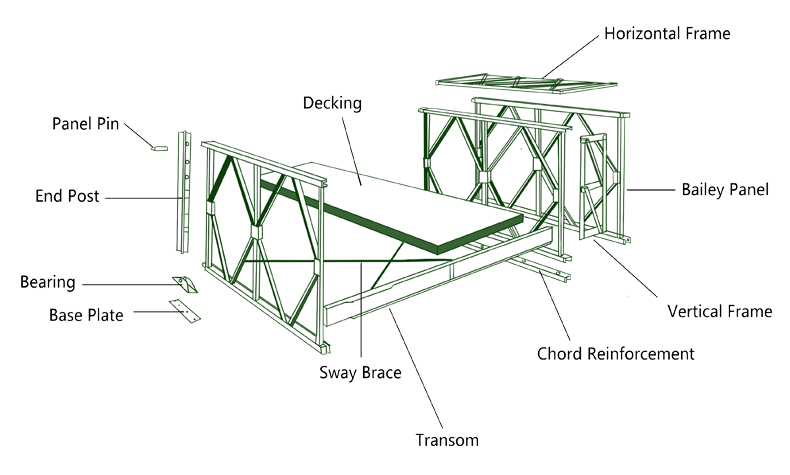

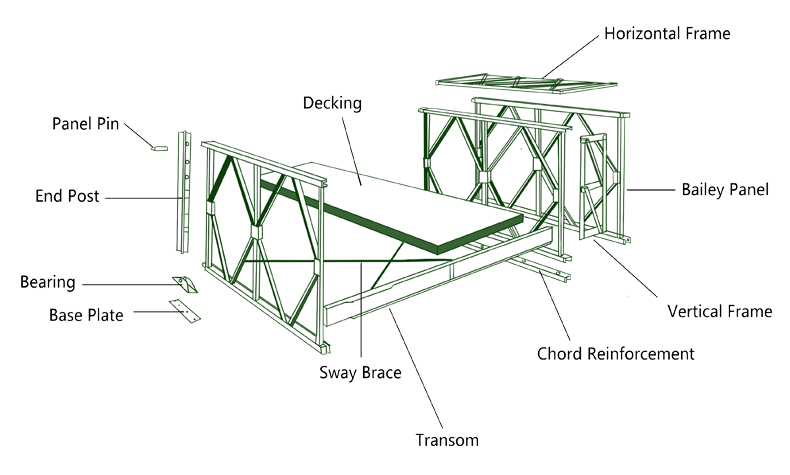

The prefabricated steel bridge features a pre-assembled modular design that significantly reduces on-site installation time. Components are lightweight yet robust, allowing for quick transportation and assembly by a small team. This characteristic is critical in emergency scenarios where every minute counts.

Constructed with high-grade weather-resistant steel, our emergency bridge can withstand extreme temperatures, heavy rainfall, and strong winds. The anti-corrosion treatment protects against rust and degradation, ensuring it performs reliably in harsh outdoor conditions. It is built to endure the rigors of disaster-stricken areas and remote locations.

The steel truss bridge design incorporates a reinforced frame that enhances stability and load-bearing capacity. It can support both passenger vehicles and heavy-duty rescue equipment, making it versatile for various emergency scenarios. The structural integrity ensures safe passage even under high-stress conditions.

The bridge’s core mechanism lies in its modular steel bridge system, where each component is pre-fabricated in our factory to exact specifications. This allows for quick on-site assembly without the need for complex tools or specialized skills. The modular design also enables easy expansion or modification of the bridge length and width as needed.

We integrate advanced anti-corrosion technology into the bridge’s design, including specialized coatings and treatments that protect steel components from environmental damage. The load-bearing mechanism is optimized through computer-aided design, ensuring even weight distribution and maximum strength with minimal material usage. This dual mechanism enhances the bridge’s durability and reliability.

| ZB200 truss press limited table | |||||||||

| structure form | |||||||||

| No | internal force | not reinforced model | reinforced model | ||||||

| SS | DS | TS | QS | SSR | DSR | TSR | QSR | ||

| 200 | standard truss moment(kN.m) | 1034.3 | 2027.2 | 2978.8 | 3930.3 | 2165.4 | 4244.2 | 6236.4 | 8228.6 |

| 200 | standard truss shear (kN) | 222.1 | 435.3 | 639.6 | 843.9 | 222.1 | 435.3 | 639.6 | 843.9 |

| 201 | high bending truss moment(kN.m) | 1593.2 | 3122.8 | 4585.5 | 6054.3 | 3335.8 | 6538.2 | 9607.1 | 12676.1 |

| 202 | high bending truss shear(kN) | 348 | 696 | 1044 | 1392 | 348 | 696 | 1044 | 1392 |

| 203 | Shear force of super high shear truss(kN) | 509.8 | 999.2 | 1468.2 | 1937.2 | 509.8 | 999.2 | 1468.2 | 1937.2 |

| ZB200 Table of geometric characteristics of truss bridge(Half bridge) | ||||

| structure | geometric characteristics | |||

| geometric characteristics | chord area(cm2) | Section properties(cm3) | Moment of inertia(cm4) | |

SS single-row, single-layer | SS single-row,single-layer | 25.48 | 5437 | 580174 |

SSR single-row,single-layer, reinforce | 50.96 | 10875 | 1160348 | |

DS double-row, single-layer | DS double-row,single-layer | 50.96 | 10875 | 1160348 |

| DSR1 double-row,single-layer, reinforced | 76.44 | 16312 | 1740522 | |

| DSR2 double-row,single-layer, reinforced only on the top | 101.92 | 21750 | 2320696 | |

TS triple-row, single-layer | TS triple-row,single-layer | 76.44 | 16312 | 1740522 |

| TSR2 triple-row,single-layer, reinforced only on the top | 127.4 | 27185 | 2900870 | |

| TSR3 triple-row,single-layer, reinforced only at the bottom | 152.88 | 32625 | 3481044 | |

| QS quadruple-row, single-layer | QS quadruple-row,single-layer | 101.92 | 21750 | 2320696 |

| QSR3 quadruple-row,single-layer, reinforced only on the top | 178.36 | 38059 | 4061218 | |

| QSR4 quadruple-row,single-layer, reinforced only at the bottom | 203.84 | 43500 | 4641392 | |

In the wake of earthquakes, floods, or hurricanes, our emergency steel bridge provides immediate access to affected areas. It helps rescue teams reach victims, deliver supplies, and restore critical infrastructure, playing a vital role in disaster response efforts.

During construction projects, unexpected issues such as bridge collapses or road damage can disrupt progress. Our temporary steel bridge serves as a quick replacement, ensuring construction continues without significant delays. It is also ideal for providing temporary access to construction sites in remote locations.

In regions with underdeveloped infrastructure, such as rural communities or remote industrial sites, the prefabricated steel bridge offers a practical solution for safe transportation. It can be deployed to cross rivers, valleys, or other obstacles, connecting isolated areas to essential services.

We use advanced intelligent cutting equipment to precision-cut steel plates and components. Skilled welders then assemble these parts using high-quality welding techniques, ensuring strong and durable joints. Each weld is inspected for quality to meet strict industry standards.

Throughout the production process, our steel bridge structures undergo multiple quality inspections. From raw material testing to final assembly checks, we ensure every component meets our high standards for strength, durability, and performance. This rigorous inspection process eliminates defects and ensures reliability.

After production, the bridge components are packaged in standardized containers to protect them during transportation. Each component is labeled clearly for easy identification, simplifying the assembly process on-site. The packaging is designed to be compact and easy to transport, even to remote locations.

①

Raw Material

②

Sawing

③

Cutting

④

Shearing

⑤

Bending

⑥

Punching

⑦

Drilling

⑧

Welding

⑨

Surface Treatment

⑩

Semi-finished Products

⑪

Painting

⑫

Finished Products

We have supplied emergency steel bridges to numerous countries for disaster relief and infrastructure projects. Our global experience has equipped us with the knowledge to adapt to diverse environmental and project requirements, ensuring customer satisfaction worldwide.

While our bridge is designed for rapid deployment, we also offer custom steel bridge solutions to meet specific customer needs. Whether it’s adjusting the bridge’s load capacity, length, or design, our team works closely with customers to deliver a product that aligns with their unique requirements.

Our team of experienced engineers and technicians provides comprehensive technical support, including installation guidance, maintenance advice, and on-site training. We are committed to ensuring customers can deploy and use our bridge with confidence, even in high-pressure emergency situations.

Our Emergency Prefabricated Steel Bridge is a game-changing solution designed for urgent access needs in critical situations. As a leading prefabricated steel bridge manufacturer, we prioritize speed, reliability, and durability in every unit we produce. This emergency steel bridge is engineered to be deployed quickly, providing immediate access in the aftermath of natural disasters, infrastructure failures, or unexpected emergencies. It adheres to global standards such as ASTM and GB, ensuring it can withstand extreme conditions while supporting safe and efficient traffic flow.

Specification | Details |

Standard | ASTM, BS, GB |

Grade | Q345B-Q460C |

Place of Origin | Jiangsu, China |

Brand Name | BAILEY |

Model Number | JSBLGQ-HD200-071 |

Type | Heavy |

Application | Steel Structure Bridge |

Tolerance | ±3% |

Supply Ability | 10000.0 Ton/Tons per Year |

Packaging Details | packing in containers or bulk |

Port of Loading | Any port of China, main port is Shanghai port |

The prefabricated steel bridge features a pre-assembled modular design that significantly reduces on-site installation time. Components are lightweight yet robust, allowing for quick transportation and assembly by a small team. This characteristic is critical in emergency scenarios where every minute counts.

Constructed with high-grade weather-resistant steel, our emergency bridge can withstand extreme temperatures, heavy rainfall, and strong winds. The anti-corrosion treatment protects against rust and degradation, ensuring it performs reliably in harsh outdoor conditions. It is built to endure the rigors of disaster-stricken areas and remote locations.

The steel truss bridge design incorporates a reinforced frame that enhances stability and load-bearing capacity. It can support both passenger vehicles and heavy-duty rescue equipment, making it versatile for various emergency scenarios. The structural integrity ensures safe passage even under high-stress conditions.

The bridge’s core mechanism lies in its modular steel bridge system, where each component is pre-fabricated in our factory to exact specifications. This allows for quick on-site assembly without the need for complex tools or specialized skills. The modular design also enables easy expansion or modification of the bridge length and width as needed.

We integrate advanced anti-corrosion technology into the bridge’s design, including specialized coatings and treatments that protect steel components from environmental damage. The load-bearing mechanism is optimized through computer-aided design, ensuring even weight distribution and maximum strength with minimal material usage. This dual mechanism enhances the bridge’s durability and reliability.

| ZB200 truss press limited table | |||||||||

| structure form | |||||||||

| No | internal force | not reinforced model | reinforced model | ||||||

| SS | DS | TS | QS | SSR | DSR | TSR | QSR | ||

| 200 | standard truss moment(kN.m) | 1034.3 | 2027.2 | 2978.8 | 3930.3 | 2165.4 | 4244.2 | 6236.4 | 8228.6 |

| 200 | standard truss shear (kN) | 222.1 | 435.3 | 639.6 | 843.9 | 222.1 | 435.3 | 639.6 | 843.9 |

| 201 | high bending truss moment(kN.m) | 1593.2 | 3122.8 | 4585.5 | 6054.3 | 3335.8 | 6538.2 | 9607.1 | 12676.1 |

| 202 | high bending truss shear(kN) | 348 | 696 | 1044 | 1392 | 348 | 696 | 1044 | 1392 |

| 203 | Shear force of super high shear truss(kN) | 509.8 | 999.2 | 1468.2 | 1937.2 | 509.8 | 999.2 | 1468.2 | 1937.2 |

| ZB200 Table of geometric characteristics of truss bridge(Half bridge) | ||||

| structure | geometric characteristics | |||

| geometric characteristics | chord area(cm2) | Section properties(cm3) | Moment of inertia(cm4) | |

SS single-row, single-layer | SS single-row,single-layer | 25.48 | 5437 | 580174 |

SSR single-row,single-layer, reinforce | 50.96 | 10875 | 1160348 | |

DS double-row, single-layer | DS double-row,single-layer | 50.96 | 10875 | 1160348 |

| DSR1 double-row,single-layer, reinforced | 76.44 | 16312 | 1740522 | |

| DSR2 double-row,single-layer, reinforced only on the top | 101.92 | 21750 | 2320696 | |

TS triple-row, single-layer | TS triple-row,single-layer | 76.44 | 16312 | 1740522 |

| TSR2 triple-row,single-layer, reinforced only on the top | 127.4 | 27185 | 2900870 | |

| TSR3 triple-row,single-layer, reinforced only at the bottom | 152.88 | 32625 | 3481044 | |

| QS quadruple-row, single-layer | QS quadruple-row,single-layer | 101.92 | 21750 | 2320696 |

| QSR3 quadruple-row,single-layer, reinforced only on the top | 178.36 | 38059 | 4061218 | |

| QSR4 quadruple-row,single-layer, reinforced only at the bottom | 203.84 | 43500 | 4641392 | |

In the wake of earthquakes, floods, or hurricanes, our emergency steel bridge provides immediate access to affected areas. It helps rescue teams reach victims, deliver supplies, and restore critical infrastructure, playing a vital role in disaster response efforts.

During construction projects, unexpected issues such as bridge collapses or road damage can disrupt progress. Our temporary steel bridge serves as a quick replacement, ensuring construction continues without significant delays. It is also ideal for providing temporary access to construction sites in remote locations.

In regions with underdeveloped infrastructure, such as rural communities or remote industrial sites, the prefabricated steel bridge offers a practical solution for safe transportation. It can be deployed to cross rivers, valleys, or other obstacles, connecting isolated areas to essential services.

We use advanced intelligent cutting equipment to precision-cut steel plates and components. Skilled welders then assemble these parts using high-quality welding techniques, ensuring strong and durable joints. Each weld is inspected for quality to meet strict industry standards.

Throughout the production process, our steel bridge structures undergo multiple quality inspections. From raw material testing to final assembly checks, we ensure every component meets our high standards for strength, durability, and performance. This rigorous inspection process eliminates defects and ensures reliability.

After production, the bridge components are packaged in standardized containers to protect them during transportation. Each component is labeled clearly for easy identification, simplifying the assembly process on-site. The packaging is designed to be compact and easy to transport, even to remote locations.

①

Raw Material

②

Sawing

③

Cutting

④

Shearing

⑤

Bending

⑥

Punching

⑦

Drilling

⑧

Welding

⑨

Surface Treatment

⑩

Semi-finished Products

⑪

Painting

⑫

Finished Products

We have supplied emergency steel bridges to numerous countries for disaster relief and infrastructure projects. Our global experience has equipped us with the knowledge to adapt to diverse environmental and project requirements, ensuring customer satisfaction worldwide.

While our bridge is designed for rapid deployment, we also offer custom steel bridge solutions to meet specific customer needs. Whether it’s adjusting the bridge’s load capacity, length, or design, our team works closely with customers to deliver a product that aligns with their unique requirements.

Our team of experienced engineers and technicians provides comprehensive technical support, including installation guidance, maintenance advice, and on-site training. We are committed to ensuring customers can deploy and use our bridge with confidence, even in high-pressure emergency situations.