Tel: +86 15262904857 E-mail: overseas@jsbaileybridge.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

As a leading manufacturer of steel structures, Jiangsu Bailey Steel Bridge specializes in producing prefabricated compact steel military temporary bridges that meet global standards. Our products are designed for durability, portability, and cost-effectiveness, making them ideal for military, infrastructure, and emergency scenarios worldwide. Below is a detailed introduction to our core product—Compact 321 Bailey Steel Bridge.

| Availability: | |

|---|---|

| Quantity: | |

CB100(CB321)Bailey Bridge

BAILEY

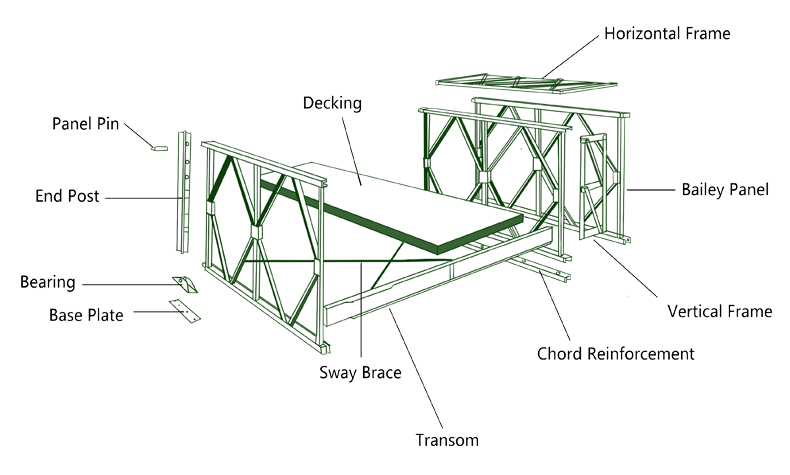

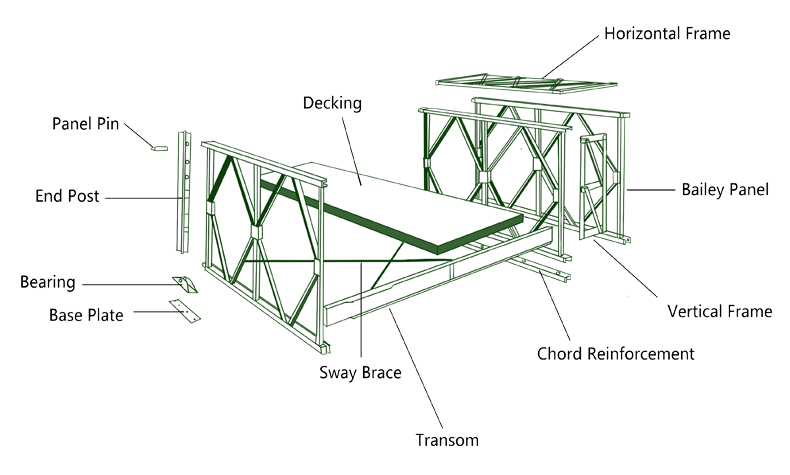

Our prefabricated compact steel military temporary Bailey Steel Bridge is a modular, lightweight structure engineered to provide rapid crossing solutions for roads, rivers, and rough terrains. Manufactured in Jiangsu, China, this product adheres to strict ASTM and GB standards, using high-strength Q355B-Q460C steel to ensure superior load-bearing capacity and longevity.

Specification | Details |

Standard | ASTM, BS, GB |

Grade | Q345B-Q460C |

Place of Origin | Jiangsu, China |

Brand Name | BAILEY |

Model Number | JSBLGQ-HD200-071 |

Type | Heavy |

Application | Steel Structure Bridge |

Tolerance | ±3% |

Supply Ability | 10000.0 Ton/Tons per Year |

Packaging Details | packing in containers or bulk |

Port of Loading | Any port of China, main port is Shanghai port |

The bridge is constructed with Q355B-Q460C high-strength steel, a material known for its excellent tensile strength and corrosion resistance. Every component meets ASTM and GB standards, ensuring consistency and reliability in harsh environments—from tropical rainforests in Cambodia to arid regions in India.

As a compact steel bridge, its modular structure allows for easy disassembly and transportation. Unlike traditional concrete bridges, our product can be shipped in bundles and assembled on-site with minimal heavy equipment, reducing logistics costs and installation time.

We prioritize "cheap prefabricated" solutions without compromising quality. The bridge’s anti-corrosion surface treatment (including painting and galvanization) extends its service life to over 15 years, while the prefabricated process cuts on-site construction costs by 30% compared to custom-built bridges.

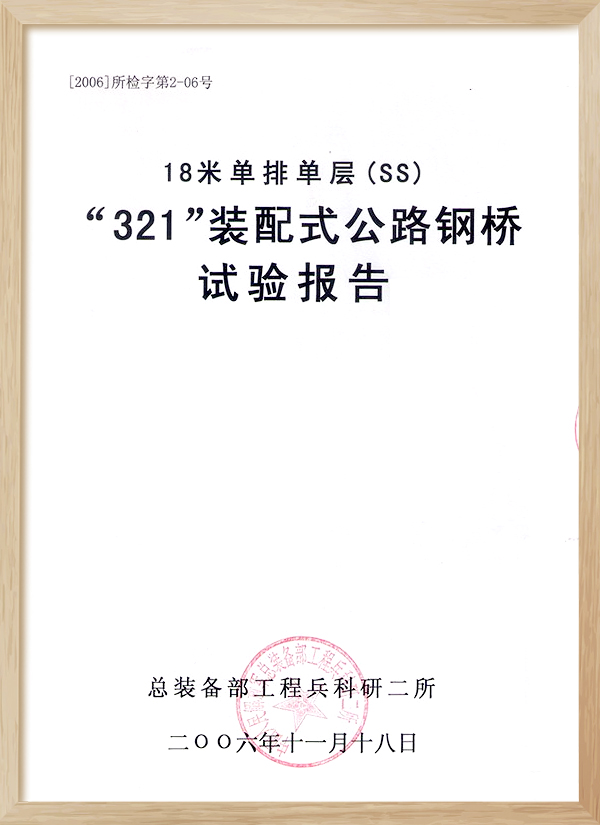

The bridge adopts the ZB321(100) truss model, a design proven for high load-bearing capacity. According to our truss press limited table, the standard truss can withstand a moment of up to 4,809.4 kN.m (reinforced model) and a shear force of 698.9 kN—sufficient to support military vehicles, heavy trucks, and pedestrian traffic.

The half-bridge’s geometric properties (e.g., section properties up to 30,641.7 cm³ and moment of inertia up to 4,596,255.2 cm⁴ for reinforced models) ensure structural stability even in uneven terrains. This design minimizes deflection and enhances resistance to wind and seismic forces.

Each component is pre-drilled and standardized, allowing for tool-free connection in most cases. A team of 5 workers can assemble a 50-meter bridge in 3 days—critical for military operations or emergency rescue (e.g., post-earthquake road restoration).

| ZB321(100) truss press limited table | |||||||||

| No. | internal force | structure form | |||||||

| not reinforced model | reinforced model | ||||||||

| SS | DS | TS | DDR | SSR | DSR | TSR | DDR | ||

| 321(100) | standard truss moment(kN.m) | 788.2 | 1576.4 | 2246.4 | 3265.4 | 1687.5 | 3375.0 | 4809.4 | 6750.0 |

| 321(100) | standard truss shear (kN) | 245.2 | 490.5 | 698.9 | 490.5 | 245.2 | 490.5 | 698.9 | 490.5 |

| 321 (100) Table of geometric characteristics of truss bridge(Half bridge) | |||||||||

| Type No. | Geometric characteristics | structure form | |||||||

| not reinforced model | reinforced model | ||||||||

| SS | DS | TS | DDR | SSR | DSR | TSR | DDR | ||

| 321(100) | Section properties(cm3) | 3578.5 | 7157.1 | 10735.6 | 14817.9 | 7699.1 | 15398.3 | 23097.4 | 30641.7 |

| 321(100) | Moment of inertia(cm4) | 250497.2 | 500994.4 | 751491.6 | 2148588.8 | 577434.4 | 1154868.8 | 1732303.2 | 4596255.2 |

As a military temporary steel bridge, it is widely used by armed forces for rapid troop and equipment deployment. Its portability and quick assembly make it ideal for temporary crossings in combat zones or remote military outposts.

The bridge supports infrastructure development, such as the Kamchay Hydropower Station in Cambodia (where it was used to transport construction materials) and India’s 225-meter deck-type bridge built for the Patel statue project. It also serves as a temporary bypass during road or bridge maintenance.

In natural disasters like earthquakes or floods, our emergency steel bridge provides immediate access to affected areas. We supplied bridges to Wenchuan (China) post-2008 earthquake to restore transportation lines quickly.

It is a top choice for projects in remote regions, such as the 10 bridges we supplied to Guinea (2018) for rural connectivity, and Nepal’s hydropower station crossings—where accessibility and durability are paramount.

We start with strict raw material quality control: every batch of Q355B-Q460C steel is tested for chemical composition and mechanical properties to meet standards.

Sawing & Cutting: Raw steel is cut into standardized lengths using CNC saws (tolerance ±1 mm).

Punching & Drilling: Precisely drilled holes ensure component compatibility during assembly.

Bending & Shearing: Components are shaped using hydraulic presses for consistent dimensions.

All welds are inspected via ultrasonic testing to avoid defects. After welding, components undergo anti-corrosion painting or galvanization to resist rust.

Finished products are checked against ISO9001:2015 certification standards. They are then bundled for shipping, with protective covers to prevent damage during transit.

①

Raw Material

②

Sawing

③

Cutting

④

Shearing

⑤

Bending

⑥

Punching

⑦

Drilling

⑧

Welding

⑨

Surface Treatment

⑩

Semi-finished Products

⑪

Painting

⑫

Finished Products

Founded in 2006, we have over 20 years of experience in manufacturing Bailey Steel Bridges. Our team includes military research institution partners, ensuring our products meet military-grade requirements.

We hold ISO9001:2015 certification, and our bridges comply with CMA, CNAS, Grade I road, and British HA/US HS25 loading standards. Every product undergoes third-party testing for quality.

Our bridges have been used in high-profile projects: India’s 225-meter Patel statue bridge, Guinea’s 10 rural bridges, and Cambodia’s Kamchay Hydropower Station. This global project experience proves our ability to adapt to diverse climates and requirements.

We offer end-to-end support:

Technical Design: Customized solutions based on client needs (e.g., pedestrian bridges, platform bridges).

Installation & Training: On-site engineer guidance for assembly.

After-Sales Maintenance: Regular follow-ups to ensure bridge performance.

Our prefabricated compact steel military temporary Bailey Steel Bridge is a modular, lightweight structure engineered to provide rapid crossing solutions for roads, rivers, and rough terrains. Manufactured in Jiangsu, China, this product adheres to strict ASTM and GB standards, using high-strength Q355B-Q460C steel to ensure superior load-bearing capacity and longevity.

Specification | Details |

Standard | ASTM, BS, GB |

Grade | Q345B-Q460C |

Place of Origin | Jiangsu, China |

Brand Name | BAILEY |

Model Number | JSBLGQ-HD200-071 |

Type | Heavy |

Application | Steel Structure Bridge |

Tolerance | ±3% |

Supply Ability | 10000.0 Ton/Tons per Year |

Packaging Details | packing in containers or bulk |

Port of Loading | Any port of China, main port is Shanghai port |

The bridge is constructed with Q355B-Q460C high-strength steel, a material known for its excellent tensile strength and corrosion resistance. Every component meets ASTM and GB standards, ensuring consistency and reliability in harsh environments—from tropical rainforests in Cambodia to arid regions in India.

As a compact steel bridge, its modular structure allows for easy disassembly and transportation. Unlike traditional concrete bridges, our product can be shipped in bundles and assembled on-site with minimal heavy equipment, reducing logistics costs and installation time.

We prioritize "cheap prefabricated" solutions without compromising quality. The bridge’s anti-corrosion surface treatment (including painting and galvanization) extends its service life to over 15 years, while the prefabricated process cuts on-site construction costs by 30% compared to custom-built bridges.

The bridge adopts the ZB321(100) truss model, a design proven for high load-bearing capacity. According to our truss press limited table, the standard truss can withstand a moment of up to 4,809.4 kN.m (reinforced model) and a shear force of 698.9 kN—sufficient to support military vehicles, heavy trucks, and pedestrian traffic.

The half-bridge’s geometric properties (e.g., section properties up to 30,641.7 cm³ and moment of inertia up to 4,596,255.2 cm⁴ for reinforced models) ensure structural stability even in uneven terrains. This design minimizes deflection and enhances resistance to wind and seismic forces.

Each component is pre-drilled and standardized, allowing for tool-free connection in most cases. A team of 5 workers can assemble a 50-meter bridge in 3 days—critical for military operations or emergency rescue (e.g., post-earthquake road restoration).

| ZB321(100) truss press limited table | |||||||||

| No. | internal force | structure form | |||||||

| not reinforced model | reinforced model | ||||||||

| SS | DS | TS | DDR | SSR | DSR | TSR | DDR | ||

| 321(100) | standard truss moment(kN.m) | 788.2 | 1576.4 | 2246.4 | 3265.4 | 1687.5 | 3375.0 | 4809.4 | 6750.0 |

| 321(100) | standard truss shear (kN) | 245.2 | 490.5 | 698.9 | 490.5 | 245.2 | 490.5 | 698.9 | 490.5 |

| 321 (100) Table of geometric characteristics of truss bridge(Half bridge) | |||||||||

| Type No. | Geometric characteristics | structure form | |||||||

| not reinforced model | reinforced model | ||||||||

| SS | DS | TS | DDR | SSR | DSR | TSR | DDR | ||

| 321(100) | Section properties(cm3) | 3578.5 | 7157.1 | 10735.6 | 14817.9 | 7699.1 | 15398.3 | 23097.4 | 30641.7 |

| 321(100) | Moment of inertia(cm4) | 250497.2 | 500994.4 | 751491.6 | 2148588.8 | 577434.4 | 1154868.8 | 1732303.2 | 4596255.2 |

As a military temporary steel bridge, it is widely used by armed forces for rapid troop and equipment deployment. Its portability and quick assembly make it ideal for temporary crossings in combat zones or remote military outposts.

The bridge supports infrastructure development, such as the Kamchay Hydropower Station in Cambodia (where it was used to transport construction materials) and India’s 225-meter deck-type bridge built for the Patel statue project. It also serves as a temporary bypass during road or bridge maintenance.

In natural disasters like earthquakes or floods, our emergency steel bridge provides immediate access to affected areas. We supplied bridges to Wenchuan (China) post-2008 earthquake to restore transportation lines quickly.

It is a top choice for projects in remote regions, such as the 10 bridges we supplied to Guinea (2018) for rural connectivity, and Nepal’s hydropower station crossings—where accessibility and durability are paramount.

We start with strict raw material quality control: every batch of Q355B-Q460C steel is tested for chemical composition and mechanical properties to meet standards.

Sawing & Cutting: Raw steel is cut into standardized lengths using CNC saws (tolerance ±1 mm).

Punching & Drilling: Precisely drilled holes ensure component compatibility during assembly.

Bending & Shearing: Components are shaped using hydraulic presses for consistent dimensions.

All welds are inspected via ultrasonic testing to avoid defects. After welding, components undergo anti-corrosion painting or galvanization to resist rust.

Finished products are checked against ISO9001:2015 certification standards. They are then bundled for shipping, with protective covers to prevent damage during transit.

①

Raw Material

②

Sawing

③

Cutting

④

Shearing

⑤

Bending

⑥

Punching

⑦

Drilling

⑧

Welding

⑨

Surface Treatment

⑩

Semi-finished Products

⑪

Painting

⑫

Finished Products

Founded in 2006, we have over 20 years of experience in manufacturing Bailey Steel Bridges. Our team includes military research institution partners, ensuring our products meet military-grade requirements.

We hold ISO9001:2015 certification, and our bridges comply with CMA, CNAS, Grade I road, and British HA/US HS25 loading standards. Every product undergoes third-party testing for quality.

Our bridges have been used in high-profile projects: India’s 225-meter Patel statue bridge, Guinea’s 10 rural bridges, and Cambodia’s Kamchay Hydropower Station. This global project experience proves our ability to adapt to diverse climates and requirements.

We offer end-to-end support:

Technical Design: Customized solutions based on client needs (e.g., pedestrian bridges, platform bridges).

Installation & Training: On-site engineer guidance for assembly.

After-Sales Maintenance: Regular follow-ups to ensure bridge performance.